Discovering a Nearly Indestructible Alloy

Date

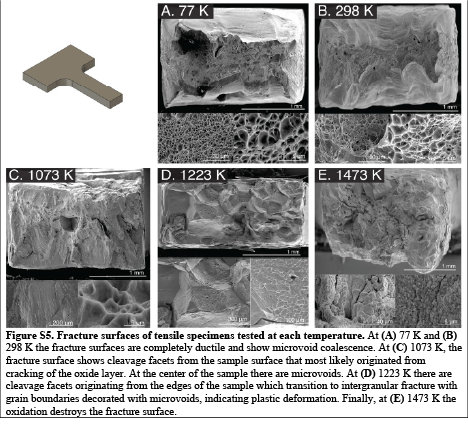

Fracture surfaces of tensile specimens tested at each temperature

Source: www.science.org

The Breakthrough at Lawrence Berkeley National Lab

Researchers at Lawrence Berkeley National Laboratory have made a groundbreaking discovery in the field of metallurgy. By combining refractory metals from the periodic table—Molybdenum, Niobium, Tungsten, Tantalum, and Rhenium—they have created an alloy that boasts remarkable properties, suitable for a wide range of applications in extreme conditions. This breakthrough could have significant implications for industries that rely on materials capable of withstanding high temperatures and severe mechanical stress.

The Challenge with Refractory Alloys

Refractory alloys are known for their exceptional resistance to heat and wear, making them invaluable in environments that require durable materials. However, these alloys typically suffer from a lack of ductility and are prone to fracturing under stress. This brittleness limits their use, especially in applications where both toughness and flexibility are required. Addressing this issue has been a longstanding challenge for materials scientists.

The NbTaTiHf Alloy

The team at Lawrence Berkley has defied the conventional limitations of refractory alloys by developing an alloy composed of Niobium, Molybdenum, Tantalum, and Hafnium. This new alloy exhibits an extraordinary combination of properties, including high fracture toughness and the ability to withstand extreme temperatures. The secret to this alloy’s exceptional performance lies in its unique structural behavior under stress.

Mechanism Behind the Toughness

The NbTaTiHf alloy forms kink bands, which are essentially microscale rotations within the crystal structure that accommodate strain. These kink bands play a crucial role in enhancing the alloy’s fracture toughness. Unlike typical refractory alloys that fracture easily, the kink bands in this alloy allow it to deform in a way that distributes strain and mitigates damage. This mechanism enables the alloy to maintain its integrity from cryogenic temperatures up to very high temperatures, a range far exceeding that of conventional materials.

Experimental Findings

The research team conducted rigorous testing to examine the strength and fracture toughness of the NbTaTiHf alloy across a temperature range from 77 to 1473 kelvin. They observed that this alloy’s fracture toughness exceeded 253 MPa·m^1/2. This remarkable performance is attributed to the dynamic interplay between screw and edge dislocations at the crack tip(region where the material experiences the highest levels of stress due to the presence of the crack). The coordinated slip of edge dislocations(defects within the crystal structure that allow the material to deform) with specific glide planes prolongs nonuniform strain through the formation of kink bands, effectively reorienting microscale bands of the crystal to accommodate localized strain and distribute damage away from the crack tip. Additional data from this experiment can be found on the science.org website.

Implications for Industrial Applications

The discovery of this nearly indestructible alloy opens up new possibilities for its use in industries that operate under extreme conditions, such as aerospace, defense, and energy. The ability to withstand a wide temperature range without compromising on strength or ductility makes this alloy particularly attractive for critical components that must endure harsh environments.

Conclusion

The innovative work by researchers at Lawrence Berkeley National Laboratory represents a significant advancement in materials science. The NbTaTiHf alloy’s unique combination of high fracture toughness and temperature resilience challenges the traditional limitations of refractory alloys. This breakthrough not only enhances our understanding of alloy behavior but also paves the way for the development of next-generation materials capable of performing in the most demanding conditions.