How Flash Joule Heating Can Benefit Metal Recyclers

Date

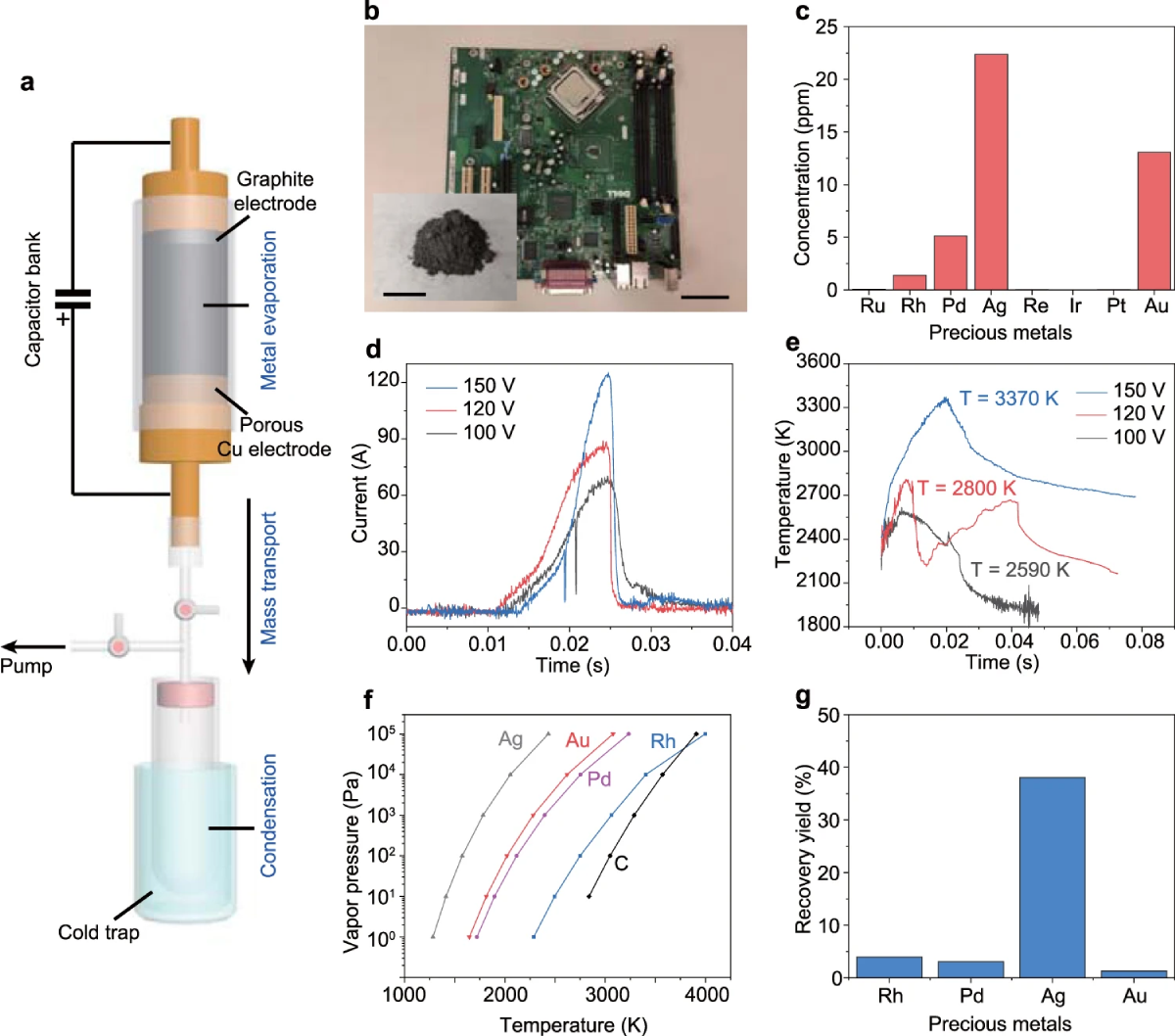

a Schematic of the FJH and evaporative separation system. The system was composed of three parts, including FJH for metal evaporation, the vacuum system for mass transport, and the cold trap for volatiles condensation. b Picture of a printed circuit board (PCB). Scale bar, 5 cm. Inset, the mixture of carbon black (CB) with PCB powder. Scale bar, 2 cm. c Concentrations of precious metals in PCB as determined by inductively coupled plasma mass spectrometry (ICP-MS). d Currents vs time recorded under different FJH voltages. e Real-time temperature measurements at different FJH voltages by fitting blackbody radiation emitted from the sample. f Vapor pressure–temperature relationship of precious metals and carbon. g Recovery yield of precious metals by condensing the evaporated gas components. The recovery yield is the average of three independent FJH experiments (n = 3).

Source: www.nature.com

Rice University’s Flash Joule Heating Discovery

As the world transitions to electric vehicles (EVs) and renewable energy storage, lithium-ion batteries seem to be everywhere. But as their use increases, so does the need for efficient recycling methods to mitigate the environmental impact. Fortunately, researchers at Rice University, led by Professor James Tour, have developed a groundbreaking method that promises to revolutionize the way we recycle lithium-ion batteries. This innovation, based on a technique called flash Joule heating (FJH), could have significant benefits for metal recyclers, including D Block Metals.

Traditional Recycling Methods are Inefficient

Current recycling processes for lithium-ion batteries rely on energy-intensive thermal or chemical methods that break down battery materials into their elemental components. These conventional techniques are not only costly but also environmentally damaging due to the high energy consumption and the release of hazardous chemicals.

With lithium-ion batteries containing valuable metals like cobalt, nickel, and lithium, which are critical for manufacturing new batteries, the demand for a more efficient and environmentally friendly recycling solution is urgent. The Rice University research team has tackled this challenge head-on, and their findings could usher in a new era of sustainable metal recovery.

Flash Joule Heating (FJH)

The key to this innovation lies in flash Joule heating, a process that involves passing a current through a moderately resistive material, rapidly heating it to extreme temperatures — in this case, 2,500 Kelvin — within seconds. This rapid heating causes the battery waste to undergo a unique transformation, creating materials with magnetic shells and stable core structures.

This magnetic property is crucial because it enables the separation and purification of valuable metals like cobalt, which are typically used in EV batteries. In fact, the research team achieved a remarkable 98% recovery of battery metals, all while preserving the structural integrity of these materials, allowing them to be reused in new batteries.

Why FJH is a Game-Changer for Metal Recyclers

For metal recyclers, this breakthrough could be transformative. Here’s why:

- Increased Efficiency and Lower Costs: Unlike traditional methods, FJH requires no solvents and operates at lower energy levels, making it a cost-effective solution for recyclers. The ability to heat and purify metals in seconds, rather than through prolonged chemical processes, saves both time and energy.

- High Purity and Yield: The process significantly reduces metal impurities while maintaining the structure and functionality of the battery materials. With a metal recovery rate of 98%, recyclers can extract more valuable materials from each batch of battery waste, increasing profitability.

- Environmentally Friendly: Traditional recycling methods generate significant waste and emissions. By contrast, FJH is a solvent-free, energy-efficient process that reduces the environmental footprint of recycling. For companies like D Block Metals, adopting such green technology would align with the growing demand for sustainable practices in the industry.

- Adaptability to Other Metals: While the Rice University study focused on lithium-ion batteries, the principles behind FJH could potentially be applied to other types of batteries and even different metal recycling streams. The ability to rapidly heat and separate materials using magnetic properties opens up new avenues for metal recovery in a variety of industries.

A Step Toward a Greener Future

As the world moves toward electrification, the need for sustainable solutions to handle battery waste will only grow. D Block Metals, as a leader in the metal recycling industry, is well-positioned to capitalize on innovations like flash Joule heating. By incorporating cutting-edge techniques, recyclers can not only improve efficiency and profitability but also contribute to a greener, more sustainable future.

The work of the Rice University team demonstrates that innovative science can have a big impact on industries like metal recycling, providing new ways to extract value from waste while minimizing environmental harm. For companies focused on the future, FJH represents a promising option for sustainability and efficiency when it comes to metal recovery.