Recycling Precious Metals From Thin Film Solar Panels

Date

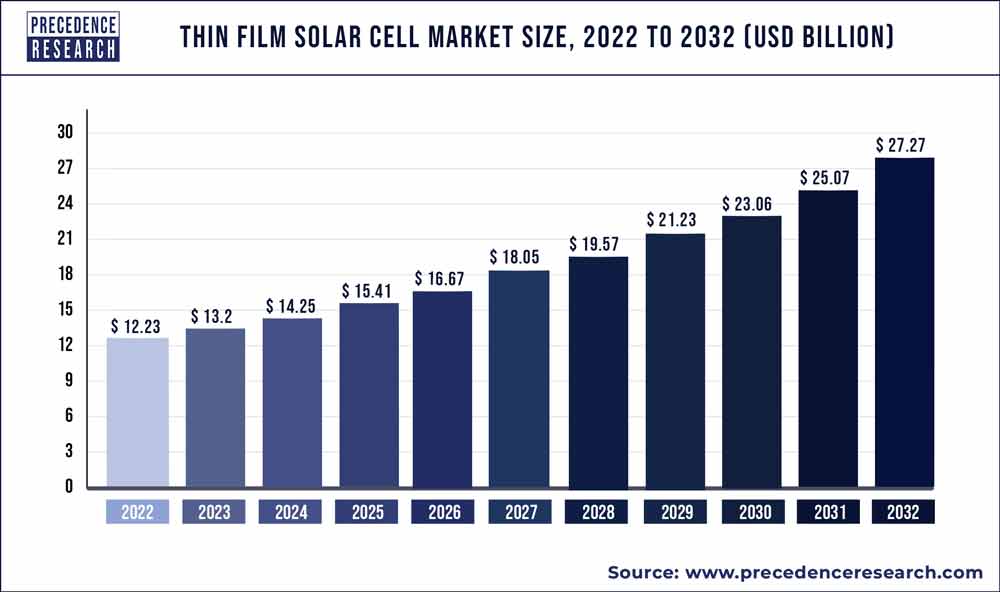

The global thin film solar cell market size was estimated at USD 12.23 billion in 2022 and is expected to hit around USD 27.27 billion by 2032 with a remarkable CAGR of 8.4% from 2023 to 2032.

Source: www.PrecedenceResearch.com

A New Commodity For Metal Recyclers?

As the demand for renewable energy grows, so does the need for efficient and sustainable recycling methods. One area experiencing rapid development is the thin-film solar cell market, which utilizes advanced technology and specialized materials, including valuable metals such as silver and indium. The rise of thin-film solar cells presents new opportunities for metal recyclers like D Block Metals to recover these precious resources while supporting a circular economy in the renewable energy sector.

The Growth of Thin-Film Solar Cells

Thin-film solar cells are an emerging technology that differs from traditional silicon-based panels, which make up about 90% of the market. These cells are created using layers of materials like copper, indium, gallium, and selenium (CIGS) to form a highly efficient photovoltaic structure. One of the key benefits of thin-film solar cells is their flexibility; they can be manufactured as bendable, lightweight panels, which makes them ideal for a variety of applications, including building-integrated photovoltaics and portable solar solutions.

The flexibility and efficiency of thin-film cells make them attractive for next-generation solar technology, but they also pose unique challenges. Unlike conventional solar panels, thin-film cells incorporate a mixture of metals, some of which are scarce or expensive. The production process generates waste that contains valuable metals, driving the need for more efficient recycling techniques to recover these materials.

Challenges and Opportunities in Metal Recovery

The increased use of metals like indium and silver in thin-film solar cells has created both challenges and opportunities for the recycling industry. Traditional recycling methods involve high heat and large amounts of chemicals, which can be costly and harmful to the environment. As the production of thin-film solar cells expands, the accumulation of production waste containing valuable metals presents a growing issue.

However, recent advancements in recycling methods have shown promise. For example, researchers at the Chalmers University of Technology in Sweden developed a new leaching-based process that allows for the recovery of up to 100% of silver and 85% of indium from thin-film solar cells. This technique uses fewer chemicals and operates at room temperature, making it more environmentally friendly and cost-effective compared to conventional methods. Such innovations could significantly improve the viability of metal recycling from solar cell production waste.

Capitalizing on the Opportunity

For metal recycling companies, the shift towards thin-film solar cells represents a prime opportunity to expand into new markets. By adopting advanced recycling techniques, metal recyclers can play a crucial role in supplying valuable materials back to the solar industry, supporting sustainable manufacturing practices and reducing reliance on virgin metal resources.

The implementation of efficient recycling methods also helps close the loop in solar panel production, allowing recovered metals to be reused in new solar cells. This not only conserves natural resources but also contributes to lowering the overall carbon footprint of solar technology. As the renewable energy sector continues to grow, metal recyclers who can offer high-quality recovered materials will be well-positioned to meet the increasing demand for metals like silver, indium, and gallium.

Developing a Circular Economy for Solar Metals

The potential for a circular economy in the solar industry is becoming more attainable with advances in metal recovery technologies. By optimizing recycling processes and improving the purity of recovered metals, the industry can reduce the environmental impact associated with mining and refining new materials. For metal recyclers, the growth of thin-film solar technology offers a chance to lead the way in sustainable practices by providing essential materials for the energy transition.

At D Block Metals, we are committed to exploring and investing in innovative recycling methods that align with the future of renewable energy. By partnering with technology developers and solar manufacturers, we aim to contribute to a more sustainable and resource-efficient world. The shift towards thin-film solar cells is not just a challenge to overcome—it’s an opportunity to redefine how we think about resource recovery in the age of clean energy.

The rise of thin-film solar cells brings new possibilities for metal recyclers to play a key role in the renewable energy sector. As technology evolves, so do the methods for recovering valuable materials from production waste. With advancements like leaching-based recycling techniques, companies such as D Block Metals can capitalize on this trend, helping to create a more circular and sustainable economy for precious metals.