How Tantalum Carbide Is Reducing Energy Loss in Electronics

Date

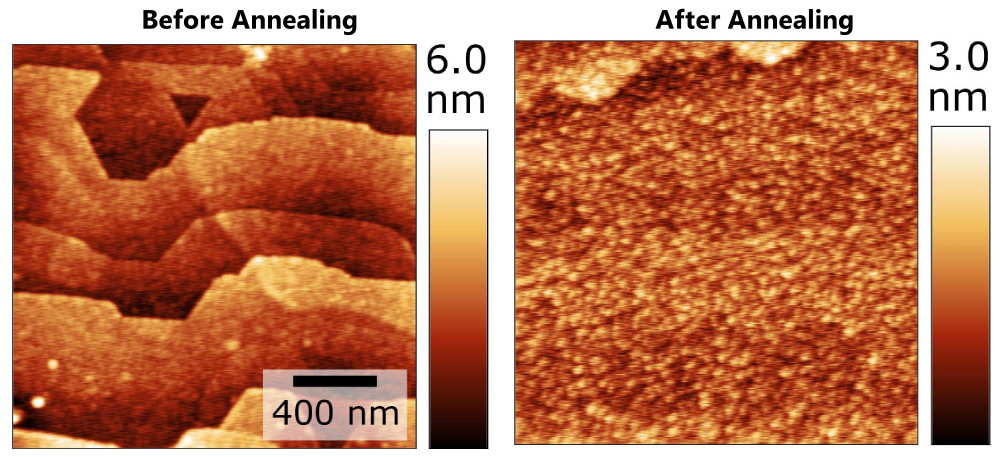

Atomic force microscopy (AFM) shows the surface of the TaC thin film before and after annealing at high temperatures. The initial film surface is composed of many columnar grains, whereas after annealing the surface has reoriented to plateaus or "step terraces." This flatter surface facilitates growth of much higher quality AlGaN layers and thus leads to higher performing electronics. Figure by Dennice Roberts, NRELSource: www.NREL.gov

The Quiet Revolution of TaC in Electronics

As global demand for electricity surges and technology evolves at breakneck speed, the need for smarter, more efficient electronic systems has never been greater. At D Block Metals, we’re committed to supporting the materials that make those systems possible. One of the most promising developments in this space? Tantalum carbide (TaC) which is a transition metal compound stepping into the spotlight for its ability to improve efficiency in next-generation power electronics.

Why Tantalum Carbide?

Tantalum carbide is a ceramic-like compound that combines the strength of tantalum with the durability of carbon. It’s known for its extreme hardness, high melting point, and most importantly for electronics, excellent electrical and thermal conductivity. But recent research has revealed another critical advantage: TaC can act as an ideal substrate for growing wide-bandgap semiconductors like aluminum gallium nitride (AlxGa₁₋ₓN).

These wide-bandgap materials are the future of powering electronics, capable of handling higher voltages and switching speeds while generating less heat. But growing them without defects has been a major hurdle, until now.

Backed by Research

A collaborative team from the National Renewable Energy Laboratory (NREL), Oak Ridge National Laboratory, and the Colorado School of Mines recently published groundbreaking work showing that TaC substrates can dramatically reduce dislocations (defects) when used to grow AlxGa₁₋ₓN. The result? Stronger, more reliable semiconductor layers that waste less energy and operate more efficiently.

Using advanced techniques like radio frequency sputtering and high-temperature annealing, researchers were able to grow high-quality AlxGa₁₋ₓN films directly on TaC. The close lattice match between the two materials, combined with similar thermal expansion properties, allowed for clean crystal growth without cracking or warping.

What This Means for Powering Electronics

By reducing defects at the atomic level, TaC enables better electron flow, fewer losses, and lower heat generation in devices like inverters, chargers, and power modules. That means smaller, more efficient systems with faster performance from EV charging stations to grid-scale renewable energy applications.

The Role of D Block Metals

As a supplier of strategic and rare transition metals, we at D Block Metals are proud to support the industries and researchers pushing the boundaries of material science. Tantalum (a d-block metal) is one of the many elements we specialize in, and the emerging role of TaC underscores the critical importance of high-performance materials in tomorrow’s technologies.

We believe this research is just the beginning. As scientists continue exploring the atomic interface between TaC and advanced semiconductors, we’ll see even more energy-saving breakthroughs driven by the unique properties of d-block metals.