Recovering Tantalum with Microwaves

Date

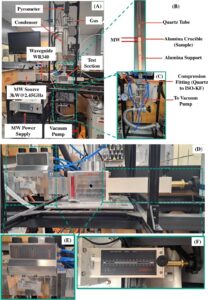

Photograph of the experimental microwave test bed. (A) Overview of the test bed components, showing the microwave source and horizontally positioned waveguide. (B) Close-up of the internal reactor section, illustrating the sample placement within the reactor. (C) A vacuum pump used to evacuate the reactor and maintain the desired partial pressure. (D) Close-up of the waveguide section featuring a (E) three-stub tuner and a (F) sliding short. (E) and (D) were used to match the load (sample’s) impedance to provide an efficient transfer of power through the waveguide. The initial positions of the stub tuner and sliding short were determined using COMSOL Multiphysics software and subsequently fine-tuned empirically.Source: www.nature.com/srep

Nature Publishing Group - Scientific Reports

Harnessing Microwave Energy for Cleaner Metal Recovery

Tantalum, a rare and indispensable metal in our digital world, plays a critical role in manufacturing the capacitors used in smartphones, laptops, medical equipment, and aerospace devices. Yet despite its high value, the majority of tantalum used in electronics is lost at end-of-life. Traditional recycling methods fail to recover it efficiently, posing both an environmental and strategic risk.

Recent research led by Dr. Terence Musho at West Virginia University’s Department of Mechanical, Materials & Aerospace Engineering, and supported in part by DARPA, has revealed a promising solution: microwave-assisted recycling. This groundbreaking process could drastically improve how we recover tantalum and manganese from e-waste.

Why Tantalum Recovery Matters

Tantalum capacitors are compact, durable, and essential to modern electronics. About one-quarter of the world’s tantalum ends up in capacitors, especially in space-constrained applications. With the global cost of tantalum around $170 per kilogram(according to Statista), it has been proven to be economically valuable. However, traditional recycling processes often bypass tantalum entirely due to the complexity and environmental impact of recovery.

The failure to reclaim this material contributes to rising global e-waste, which reached over 62 million metric tons in 2022. Much of it ends up in landfills or is handled using unsafe methods abroad. For a metal so tightly tied to national defense and technological infrastructure, continued reliance on foreign imports presents growing vulnerabilities.

The Microwave-Assisted Breakthrough

Dr. Musho’s team developed a novel process that uses microwave energy to extract tantalum and manganese from shredded capacitors. Here’s how it works:

- Discarded tantalum capacitors are pulverized and mixed with carbon.

- When exposed to targeted microwave energy, the carbon absorbs the heat rapidly.

- This initiates carbothermal reduction, converting tantalum compounds into tantalum carbide.

- The resulting material is of high purity (over 97%) and much easier to recover.

This process bypasses the use of caustic chemicals and significantly reduces energy consumption and toxic waste. It offers a cleaner, safer, and more cost-effective alternative to traditional metal extraction.

Backed by Strategic Investment

The research received funding from DARPA under its Recycling at the Point of Disposal (RPOD) initiative. This support underscores the growing recognition that domestic recycling of critical materials like tantalum is not just an environmental concern but a matter of national security. Supply disruptions in critical metals can impact everything from telecommunications to military readiness.

By investing in technologies that reclaim vital resources at scale, the U.S. takes a step toward reducing dependence on foreign supply chains and building resilience in key manufacturing sectors.

Economic and Environmental Potential

The implications are wide-reaching. If scaled successfully, this method could:

- Make e-waste recycling more profitable for industry

- Reduce harmful landfill waste and unsafe overseas processing

- Secure a stable domestic supply of rare metals

- Lower the environmental footprint of electronics production

The research team is now piloting the technology using larger volumes of e-waste from real-world sources, including server farms and telecommunications hardware. If commercialized, this could mark the beginning of a new era in sustainable resource recovery.

At D Block Metals, we believe the future of metal supply chains must be circular. The innovative use of microwave technology in reclaiming critical metals like tantalum represents a major step forward. With continued support and industry adoption, this advancement could help transform electronic waste from a liability into a valuable domestic asset that helps ensure both economic and environmental gains for generations to come.