Hafnium Oxide: A Game-Changer in Reducing the Energy Demands of Internet and Communications Technologies

Date

Source: www.AKCP.com

In an age where digital connectivity is at the heart of our daily lives, the demand for faster and more efficient internet and communication technologies continues to increase. However, this exponential growth in data consumption also raises concerns about energy consumption and its environmental impact. Fortunately, hafnium oxide is a material that has the potential to revolutionize the way we power our digital world.

The Energy Challenge

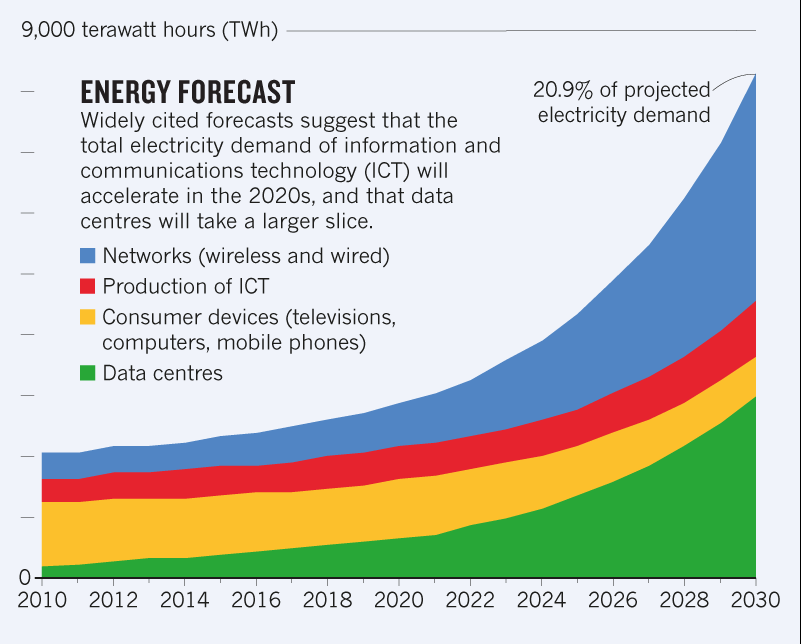

The internet and communications technologies have made tremendous strides over the years. From 2G to 5G and copper cables to fiber optics, these advancements have significantly enhanced data transmission rates. However, the growing energy demands associated with these technologies have raised concerns, especially as we move towards even more data-intensive applications such as the Internet of Things, Artificial Intelligence, and Virtual Reality.

Data centers, which house the servers that store and process online data, are well known for their high levels of energy consumption. According to the International Energy Agency (IEA), data centers were responsible for 1% of global electricity use in 2019, and their energy consumption is predicted to double by 2030 if not addressed. To sustain our digital revolution and minimize its environmental impact, we need to find innovative solutions to reduce the energy demands of these technologies. One promising solution is hafnium oxide.

The Role of Hafnium Oxide

Hafnium oxide, a compound of hafnium and oxygen, is making its way into the world of microelectronics, holding great promise for reducing the energy footprint of internet and communication technologies. Its unique properties make it an ideal candidate for enhancing the energy efficiency of digital devices, particularly transistors.

High-K Dielectric Material: One of the primary applications of hafnium oxide is in the production of high-k dielectric materials. In transistors, the dielectric material acts as an insulator between the gate electrode and the channel, controlling the flow of electrons. Hafnium oxide has a higher dielectric constant (k-value) compared to traditional silicon dioxide, which means it can maintain the same level of performance with a thinner layer. This translates to lower leakage currents and reduced power consumption in transistors.

Compatibility with Advanced Semiconductor Technologies: Hafnium oxide is compatible with state-of-the-art semiconductor fabrication processes. It can be integrated seamlessly into the production of advanced microchips, allowing for improved performance and energy efficiency without requiring a complete overhaul of existing manufacturing infrastructure.

Improved Scaling and Performance: As electronic devices continue to shrink in size, the industry faces challenges in maintaining performance while reducing power consumption. Hafnium oxide offers a solution by allowing manufacturers to scale down transistor dimensions while maintaining or even improving their performance. This scaling can lead to more energy-efficient devices without compromising speed.

Hafnium oxide’s potential goes beyond traditional transistors. Its applications can be extended to various components of modern communication technologies, such as amplifiers, capacitors, and memory devices. By incorporating hafnium oxide into these components, we can further enhance energy efficiency and reduce the overall power consumption of communication devices and networks. By enhancing the energy efficiency of microelectronics, hafnium oxide can help reduce the energy demands of internet and communication technologies, thus creating a more sustainable digital world for us all.