How Direct Lithium Extraction Will Revolutionize The EV Market

Date

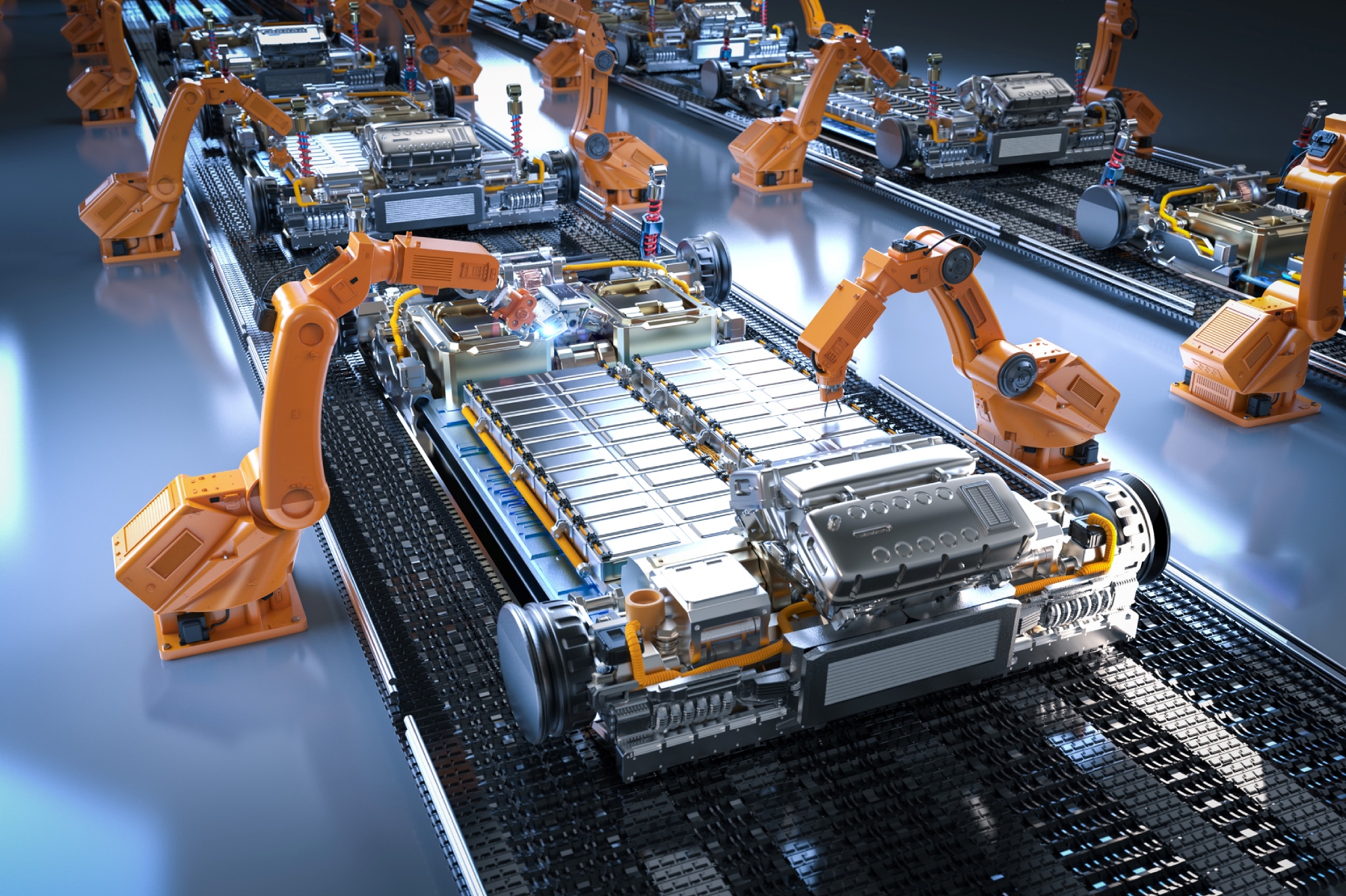

The Electric Vehicle (EV) industry has been gaining significant traction in recent years in tandem with concerns about climate change and the need for sustainable transportation. However, the surge in demand for EVs has also raised concerns about the availability and sustainability of critical materials, such as Lithium, which are crucial for manufacturing lithium-ion batteries. To address this challenge, Direct Lithium Extraction (DLE) methods are emerging as a promising solution that can meet the soaring demand of the EV market while ensuring a more efficient and sustainable supply chain.

Enhancing Lithium Production Efficiency

Traditional Lithium extraction methods, such as brine evaporation and hard-rock mining, often suffer from long processing times, high costs, and environmental impact. Direct Lithium Extraction technologies aim to overcome these limitations by significantly improving lithium production efficiency. These methods allow for the extraction of Lithium directly from brine, clay deposits, and even geothermal fluids, resulting in a shorter production cycle and a reduced environmental footprint.

Unlocking Lithium Resources

Direct Lithium Extraction techniques enable the extraction of lithium from previously untapped sources, expanding the available lithium reserves. For instance, Lithium can be efficiently extracted from geothermal brines, which are abundant in many regions worldwide. By utilizing these untapped resources, DLE technologies can help meet the increasing Lithium demand without excessive reliance on limited traditional sources.

Minimizing Environmental Impact

One of the significant advantages of Direct Lithium Extraction methods is their potential to minimize the environmental impact associated with Lithium production. Conventional methods often involve large-scale water consumption and the release of greenhouse gases, leading to ecological disruption. In contrast, DLE technologies typically use less water and have a smaller carbon footprint, making them more sustainable alternatives. These methods can also help in the responsible management of waste streams, reducing environmental contamination risks.

Faster and More Scalable Production

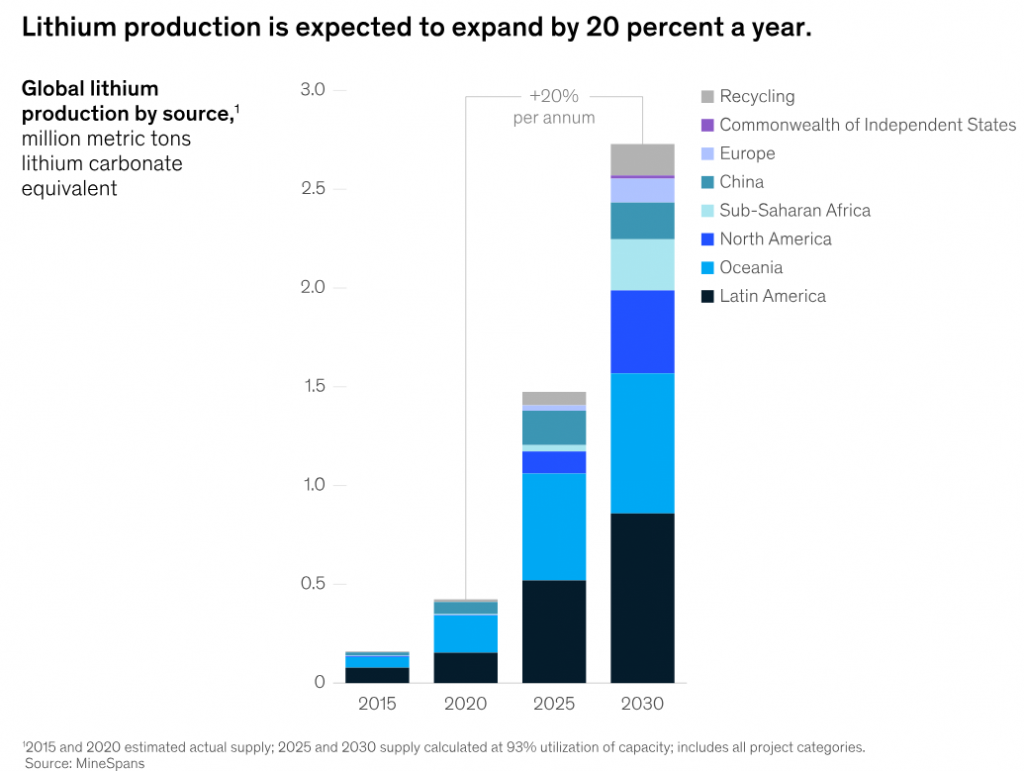

As the demand for EVs continues to surge, it is crucial to ensure that lithium production can keep pace. Direct lithium extraction techniques offer faster and more scalable production capabilities compared to traditional methods. With their ability to streamline the extraction process, DLE technologies can contribute to the mass production of Lithium, thus meeting the growing demand for Lithium-Ion batteries used in EVs.

A Catalyst for Technological Advancements

The adoption of Direct Lithium Extraction methods is not only beneficial for meeting the demand of the EV market but also serves as a catalyst for technological advancements. As companies invest in the development and optimization of DLE technologies, the entire Lithium production ecosystem will witness innovation and progress. This can lead to improvements in Lithium extraction efficiency, cost reduction, and the development of more sustainable and environmentally friendly techniques, further strengthening the foundation of the EV market.

A Promising Future For Electric Mobility

Direct Lithium Extraction represents a promising solution to meet the skyrocketing demand for Lithium-Ion batteries in the EV market. By enhancing production efficiency, unlocking untapped resources, minimizing environmental impact, and enabling faster and more scalable production, DLE technologies are poised to revolutionize the lithium supply chain. As the EV industry continues to expand, the adoption and advancement of Direct Lithium Extraction methods will play a vital role in ensuring a sustainable and thriving future for electric mobility.