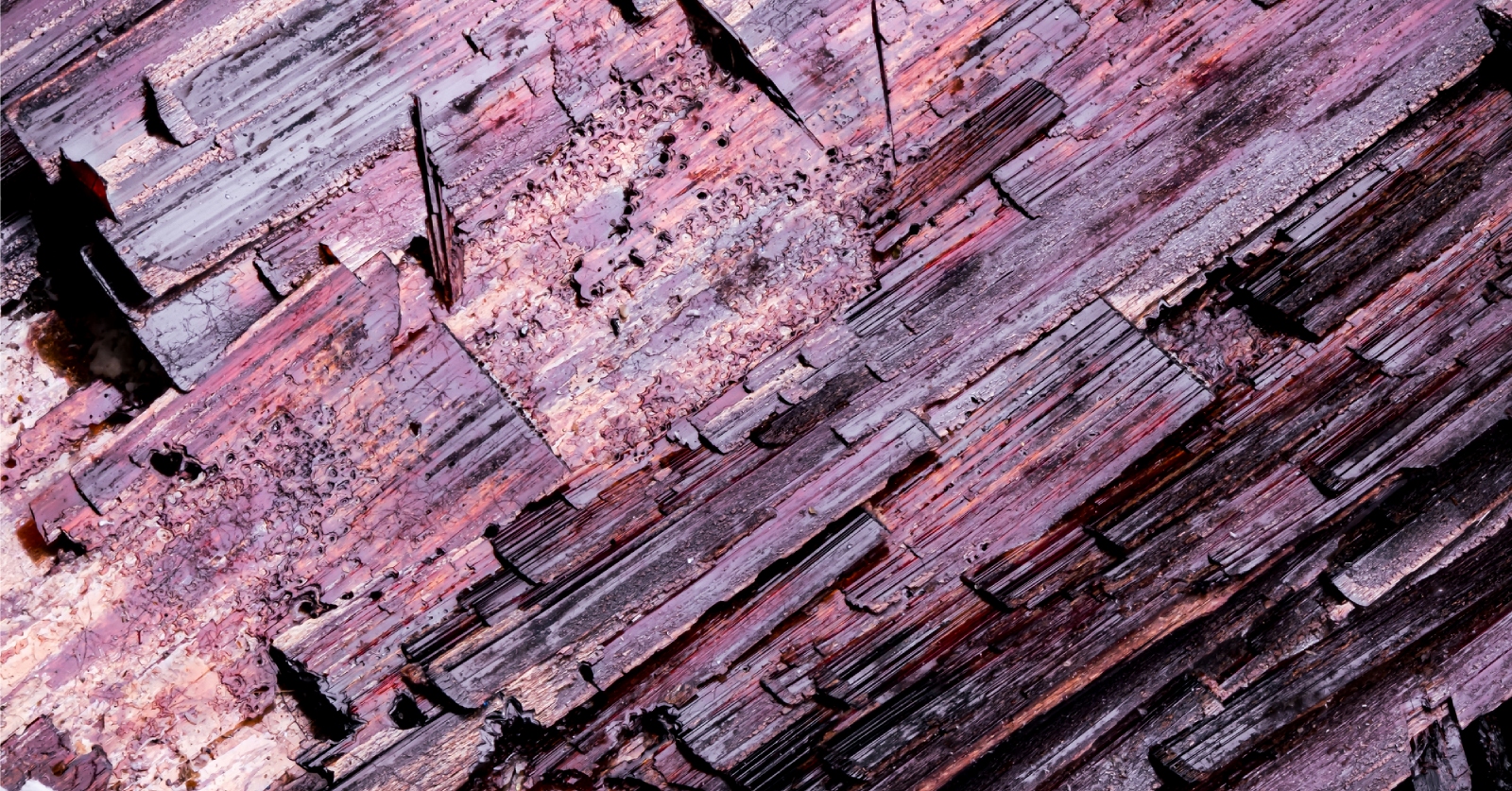

NC Veins Are Rich With Tungsten

Date

Tungsten Queen Mine Historical Marker -Location: US 15 at Buckhorn Rd. -County: Granville -Original Date Cast: 2021

Source: www.dncr.nc.gov

How North Carolina Could Revive Tungsten Production to Boost U.S. Self-Sufficiency

Tungsten is a critical metal for industries ranging from aerospace and defense to electronics and manufacturing, thanks to its high melting point and strength. However, the United States remains heavily dependent on imports for Tungsten, primarily from China, which accounts for over 80% of global production. North Carolina, with its rich mining history and known Tungsten deposits, could play a pivotal role in reducing this dependence.

The historic Tungsten Queen Mine in Vance County, North Carolina, was once the largest producer of Tungsten in the United States. Reviving mining operations in this region could not only contribute to global Tungsten production but also strengthen U.S. self-sufficiency in this strategic resource.

A Legacy of Tungsten Mining

The Tungsten Queen Mine operated from 1942 to 1971 and was a major source of tungsten during its peak. According to the U.S. Geological Survey (USGS), the mine produced significant quantities of scheelite, a tungsten-bearing mineral. While the mine closed due to fluctuating tungsten prices and declining demand in the mid-20th century, modern advancements in mining technology and rising global demand could make reopening the mine economically viable.

Global Importance of Tungsten

Tungsten is indispensable for many industries due to its unique properties:

- Aerospace and Defense: Tungsten alloys are used in high-performance jet engines and military equipment.

- Industrial Manufacturing: Tungsten carbide tools are essential for cutting and drilling in manufacturing.

- Electronics: Tungsten’s conductivity makes it a key component in semiconductors and other electronic devices.

As these industries expand, the demand for Tungsten continues to grow, making it essential for the U.S. to secure a reliable domestic supply.

Challenges and Opportunities for Mining

Reviving Tungsten mining in North Carolina faces challenges, including environmental regulations, high extraction costs, and competition from global producers. However, the opportunities could possibly outweigh the obstacles:

- Technological Advances: New mining techniques and technologies could make it easier to extract and process Tungsten economically.

- Federal Support: Tungsten is classified as a critical mineral by the U.S. government, making mining operations eligible for grants and incentives aimed at reducing import reliance.

The Role of Metal Recycling in Meeting Tungsten Demand

While mining offers one solution, secondary sources of Tungsten from industrial scrap play an important role in meeting current demand. Recycling Tungsten is not only cost-effective but also environmentally friendly. D Block Metals plays a vital role in this effort by recovering and processing Tungsten from industrial byproducts and scrap.

Why Recycling is Critical

- Rapid Deployment: Recycling Tungsten from secondary sources can quickly supplement supply without the delays associated with opening new mines.

- Sustainability: Tungsten recycling reduces the environmental impact of mining operations, contributing to a more sustainable supply chain.

- Cost Efficiency: Extracting Tungsten from industrial scrap is often more economical than mining, especially during periods of high demand.

A Balanced Approach

To secure a reliable supply of Tungsten, the U.S. must adopt a balanced approach that includes both mining and recycling. North Carolina’s historical significance in Tungsten mining, combined with the growing capabilities of metal recyclers like D Block Metals, positions the state as a potential leader in bolstering U.S. self-sufficiency.

Reviving Tungsten production in North Carolina would not only honor its mining legacy but also address a critical need in modern industry. By leveraging both primary mining operations and secondary recycling efforts, the U.S. can reduce its reliance on imports and secure a sustainable supply of this critical mineral for the future.