New Nickel-Based Alloy Could Reshape Recycling Markets

Date

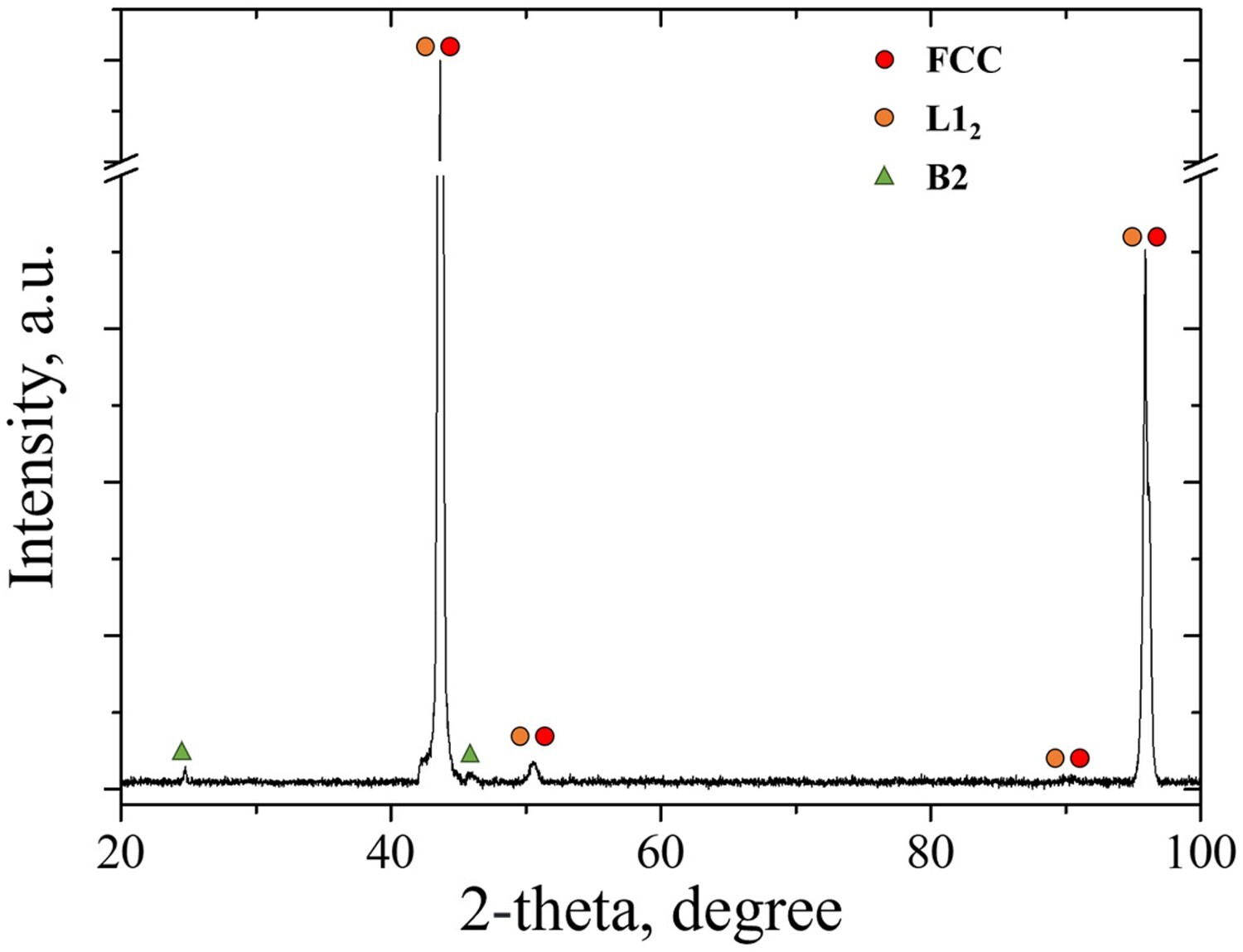

XRD pattern of as-cast Ni–HEA sample.

Hyojin Park, Sujung Son, Soung Yeoul Ahn, Hyojeong Ha, Rae Eon Kim, Jae Heung Lee, Hyo Moon Joo, Jung Gi Kim & Hyoung Seop Kim of POSTECH (Pohang University of Science and Technology).Source: www.tandfonline.com

A Temperature-Stable Alloy Could Heat Up Demand for Recycled Nickel

In a big step forward for materials science, researchers have unveiled a groundbreaking nickel-based high-entropy alloy (HEA) that could revolutionize industries ranging from aerospace to energy. But here at D Block Metals, we’re just as interested in how this alloy nicknamed the Hyperadaptor could disrupt the U.S. nickel recycling market.

What Is the Hyperadaptor?

This newly developed alloy, described in a 2025 peer-reviewed study, maintains impressive strength and ductility across a huge temperature range from cryogenic 77 K to a scorching 873 K. Engineered with tiny strengthening particles and a stable internal structure, this nickel-rich alloy stays strong and flexible no matter the temperature.

In short, the Hyperadaptor resists brittleness in the cold, maintains strength under heat, and avoids the typical degradation seen in most metals during thermal cycling. The implications for manufacturing, defense, and infrastructure are immense.

Why the U.S. Recycling Market Should Pay Attention

At D Block Metals, we closely monitor how shifts in alloy demand affect base metal markets, especially nickel. Here’s why this discovery matters:

- Nickel Content Drives Demand: The Hyperadaptor alloy contains over 35% nickel. If mass production of this material becomes viable, demand for high-purity nickel could skyrocket, especially from the aerospace and energy sectors looking for thermally stable, low-maintenance materials.

- Recycled Nickel Gains Value: Currently, recycled nickel competes with mined nickel in cost and quality, depending on the grade. However, the tight compositional tolerances required by materials like Hyperadaptor HEAs, may push manufacturers to seek recycled nickel with stricter purity standards thus creating new opportunities for recyclers who are experienced with nickel.

- Supply Chain Disruption Potential: U.S. nickel production is limited, with much of the raw material imported. If demand for Hyperadaptor-type alloys increase, it may stress existing supply chains, elevating the strategic importance of domestic recycling operations as secondary suppliers.

- Strategic Material Classification: Like other nickel-based superalloys, this HEA may eventually be classified as a critical or strategic material. That could trigger government-backed initiatives to secure domestic sources, including post-industrial nickel recovery and closed-loop recycling.

Scaling Production

Mass production is not a guarantee but if achieved, the effects on the recycling ecosystem could be fast. The Hyperadaptor’s alloying elements (Ni, Fe, Co, Cr, Al, Ti) are relatively common in high-performance scrap streams. With proper sorting and refining, U.S. recyclers could become a primary source of feedstock for these advanced alloys.

This would likely require upgraded recovery and separation technologies to isolate nickel and cobalt at a higher purity level which is something D Block Metals is already exploring through proprietary sorting and refining methods.

The Road Ahead

We don’t yet know if Hyperadaptor alloys will enter large-scale commercial production. But the mechanical stability and elemental efficiency of this Ni-based HEA make it a strong contender for next-generation applications in defense, aerospace, and renewable energy. If it does scale, the U.S. recycling market could shift from being a secondary nickel supplier to a strategic one, especially if policymakers push for sustainable sourcing and reduced import dependence.

At D Block Metals, we’re staying ahead of the curve. Our investments in alloy-specific metal recovery position us to serve industries transitioning to high-performance HEAs. Whether you’re a manufacturer, OEM, or recycler, it’s a good idea to monitor the demand for this new high-entropy alloy.