The Future In Recycling Metals

Date

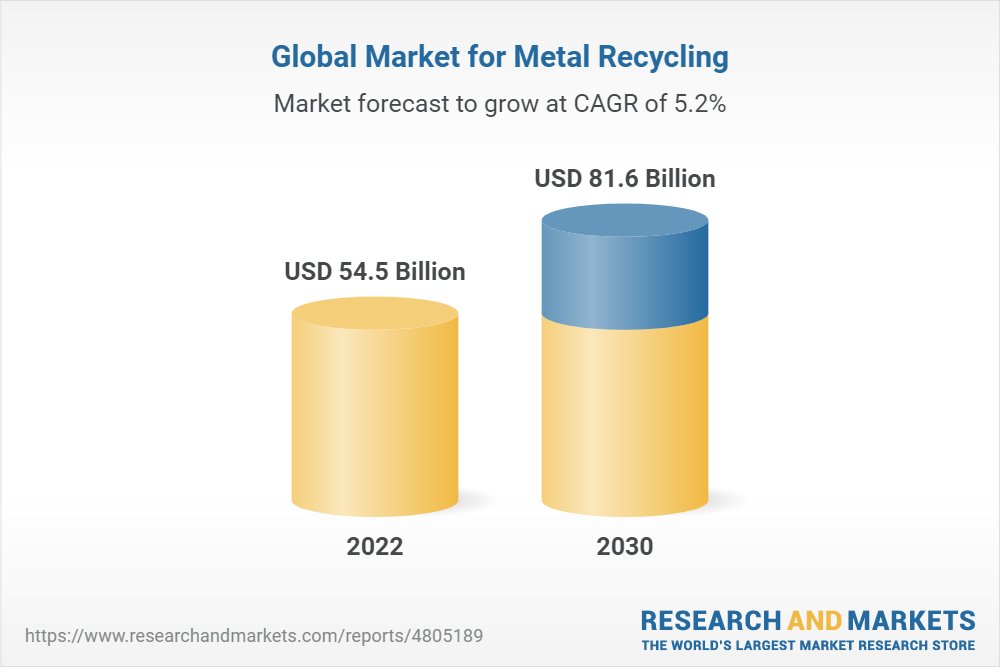

The scrap metal recycling market is expected to exceed $81.6 Billion by 2030, expanding at a CAGR of approximately 5.2% over the next seven years. Growing automotive and construction industries have had an increasing demand for metals used in manufacturing parts and infrastructure. These material-demanding industries are turning to recycled metals for their manufacturing needs and driving the boost in the scrap metal recycling market. There are many reasons recycled metal is continuously gaining popularity as a choice for companies over new metal. However, the top contributing factors include rising mining costs, environmental concerns, and the limited availability of natural resources on the earth.

Earth metals are limited in availability and the rising high mining costs are encouraging the scrap recycling market to meet the demand for raw materials. Higher energy costs and tighter environmental regulations are driving up the price of mining earth for raw metals. Urban mining is a great alternative and refers to the recycling process of retrieving precious metals such as gold and copper from discarded appliances and electronics. Researchers have found that the process of urban mining is 13 times less expensive than mining earth.

Concerns about deteriorating air quality and greenhouse gas emissions are rising, contributing to the increased demand for recycled materials. Metal recycling has distinctive attributes that reduce pollution and conserve energy while saving valuable raw metals necessary to meet the demands of various industries. Reducing mining emissions and preserving natural resources is a huge environmental benefit to urban mining. Metals can be infinitely recycled without any degradation in quality, and obtaining materials that have already been mined reduces waste. Companies can use recycled metals to meet their carbon goals and pass environmental waste audits, without compromising their product. According to the Bureau of International Recycling, 40% of steel production is made from scraps. Thus, as scrap metal recycling becomes even more efficient, it may reduce the need for mining new materials.

In addition to the expensive nature of mining and the environmental concerns it brings, recycled metal can by step resource nationalism. Resource nationalism refers to the idea that a country with a natural resource will exercise control over that resource and possibly raise prices for the rest of the world. By recycling metal, it can be easier to avoid any price inflation caused by countries attempting to control their resources. Recycled metal also saw a higher demand due to the pandemic. The pandemic has created space for more recycled materials to enter the market, especially steel. Imported steel is less available than it was before the pandemic due to shutdowns and quarantines in manufacturing hubs. Companies are turning to recycled materials to meet their manufacturing needs for being both cost-effective and better for the environment.

In conclusion, with the demand for metals growing, along with increased mining costs and environmental concerns, metal recycling has become the key for material-demanding industries to obtain the resources they need.