The Role of Transition Metals in Achieving Net-Zero

Date

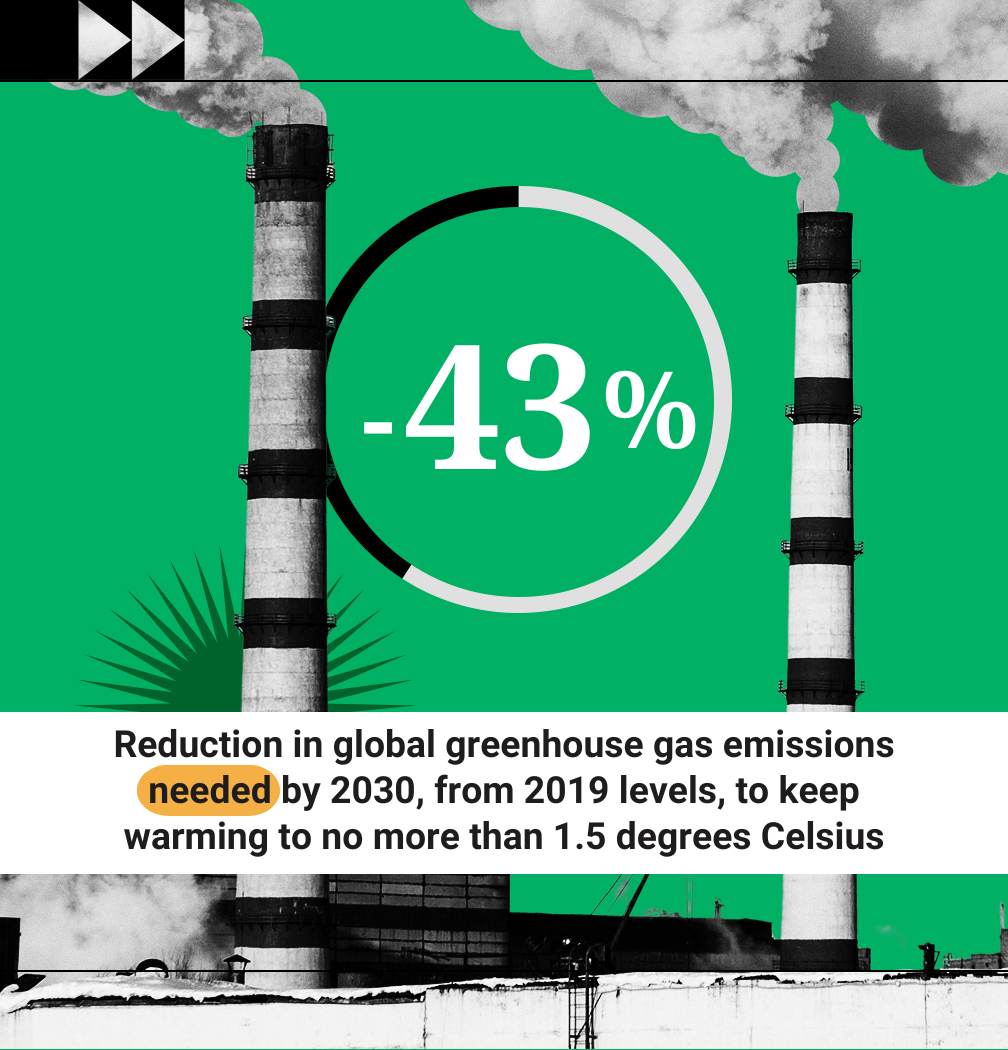

Reduction in global greenhouse gas emissions needed by 2030, from 2019 levels, to keep warming to no more than 1.5 degrees Celsius.Source: www.UN.org

Essential Metals for Achieving Net-Zero Emissions

As the global community strives to mitigate climate change, the concept of net-zero emissions has emerged as a pivotal goal. Net-zero refers to achieving a balance between the greenhouse gases emitted into the atmosphere and those removed or offset. This transition hinges on widespread adoption of renewable energy technologies, electrification of transportation, and decarbonization of industries—each of which depends on the availability of specific transition metals.

The Need for Transition Metals

Transition metals like lithium, cobalt, nickel, copper, and rare earth elements (REEs) are critical to building the infrastructure necessary for a net-zero world. From lithium-ion batteries in electric vehicles (EVs) to permanent magnets in wind turbines, these metals form the backbone of green technology. However, meeting the growing demand for these materials presents challenges in terms of extraction, processing, and ethical sourcing.

Lithium

Lithium is a cornerstone of modern batteries due to its light weight and high energy density. It powers electric vehicles, portable electronics, and grid-scale energy storage systems. While lithium is abundant in the Earth’s crust, most reserves are concentrated in a few countries like Australia, Chile, and Argentina. Processing bottlenecks and geopolitical considerations make lithium a key focus for securing sustainable supply chains.

Cobalt

An essential component of lithium-ion battery cathodes, cobalt improves energy density and stability. Over 70% of the world’s cobalt is mined in the Democratic Republic of the Congo (DRC), often under conditions that raise ethical and environmental concerns. Efforts to source cobalt responsibly and recycle it from used batteries are vital to reducing reliance on new mining operations.

Nickel

Nickel, used in battery chemistries and stainless steel production, is poised to play an even larger role in the future. Its widespread availability across various countries mitigates supply risks, but demand is expected to surge as EV adoption accelerates.

Rare Earth Elements (REEs)

REEs like neodymium and praseodymium are crucial for manufacturing powerful magnets used in wind turbines and electric motors. These elements, while abundant in nature, are rarely found in concentrated, economically extractable deposits. China dominates global REE production, creating vulnerabilities in supply chains for other nations.

Copper

Copper, known for its excellent conductivity, is indispensable in renewable energy systems and electric vehicles. Solar panels, wind turbines, and EV charging infrastructure rely heavily on copper wiring and components. The anticipated doubling of copper demand by 2050 underscores its importance.

Challenges in Achieving Net-Zero

While these metals are fundamental to net-zero technologies, their extraction and processing pose significant challenges:

- Environmental Impact: Mining and refining metals are energy-intensive processes that often rely on fossil fuels. This creates a paradox where materials needed for decarbonization contribute to emissions. Innovations in cleaner extraction and refining methods are critical.

- Ethical Sourcing: The mining industry has a history of human rights abuses, including forced labor and child labor, particularly in artisanal mining operations. Organizations and regulations like the EU Conflict Minerals Regulation aim to address these concerns.

- Supply Constraints: The geographic concentration of some critical metals, such as REEs in China and cobalt in the DRC, poses risks of supply disruptions. Recycling and developing alternative materials can alleviate these pressures.

- Recycling: Current recycling rates for critical metals are alarmingly low. Building a circular economy where metals are reused and recycled will be essential for reducing the environmental footprint of green technologies.

Innovative Solutions for Sustainable Mining

The mining industry is undergoing a transformation to align with the goals of net-zero. Efforts include:

- Decarbonizing Processing: Exploring technologies like solvent extraction and electrified smelting to reduce carbon emissions during metal processing.

- Onshore Value Addition: Encouraging resource-rich countries to process raw materials locally to reduce transportation emissions and promote economic equity.

- Formalizing Artisanal Mining: Programs like the Mutoshi pilot project in the DRC demonstrate how integrating artisanal miners into formal supply chains can improve safety and livelihoods.

The transition to a net-zero future is as much about innovation and ethics as it is about technology. Transition metals are indispensable to the green revolution, yet their extraction, processing, and recycling require thoughtful strategies to minimize environmental and social impacts. At D Block Metals, we are committed to fostering sustainable practices in the metal recycling and mining industries to power a cleaner, greener world. By working together across industries, governments, and communities, we can achieve a net-zero future that balances environmental stewardship with economic opportunity.