Turning Waste into Gold

Date

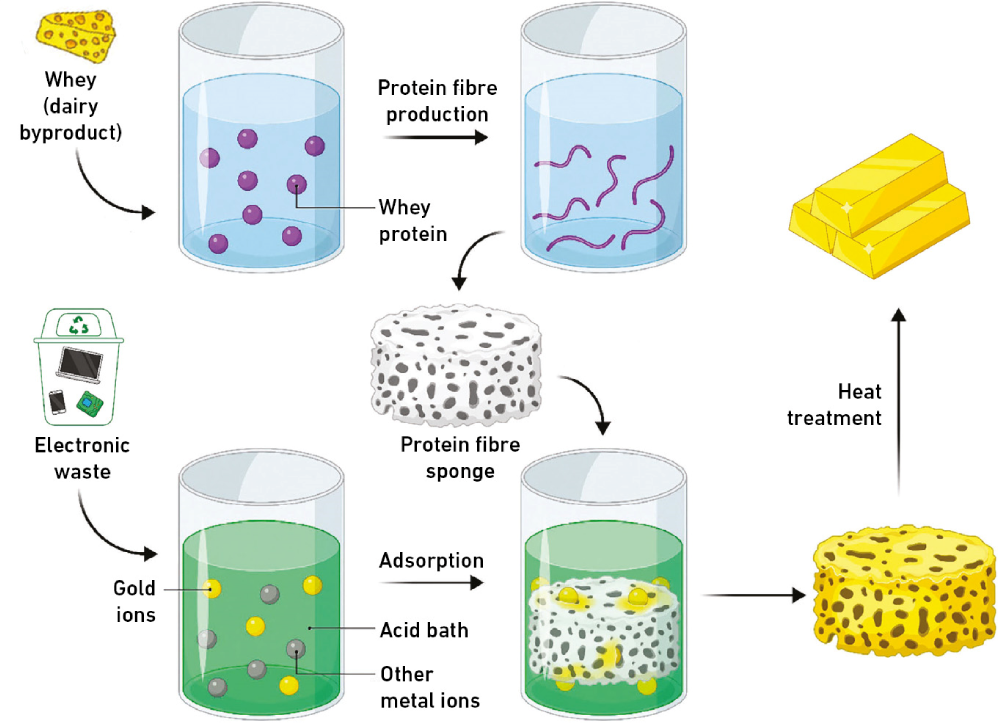

How the gold is recovered: Gold ions adhere to a sponge of protein fibrils. (Source: Peydayesh M et al. Advanced Materials, 2024, adapted)

Source: www.ethz.ch

A Game-Changer for Refractory and Precious Metal Processors

At D Block Metals, we are always on the lookout for innovative technologies that can revolutionize our industry. One such groundbreaking discovery comes from ETH Zurich, where researchers have developed a sustainable method to recover gold from electronic waste using a protein fibril sponge derived from whey(the part of cheese containing water that separates from curds), a byproduct of the food industry. This advancement promises significant implications for processors of refractory and precious metals like us.

A Sustainable Approach to Gold Recovery

The unique method, led by Professor Raffaele Mezzenga and his team, utilizes protein fibril sponges to extract gold efficiently from electronic waste. By denaturing whey proteins under acidic conditions and high temperatures, the researchers created a sponge capable of selectively adsorbing gold ions from a dissolved metal solution. The result is a cost-effective and environmentally friendly way to recover precious metals from discarded electronics.

Impact on Refractory and Precious Metal Processing

For metal recycling companies like D Block Metals, this discovery offers several potential benefits:

Cost Efficiency: The new method significantly reduces the cost of gold recovery. As Mezzenga’s calculations indicate, the procurement and energy costs for the process are 50 times lower than the value of the recovered gold. This cost efficiency can enhance our profitability and competitiveness in the market.

Environmental Sustainability: Traditional methods of recovering gold from electronic waste often involve energy-intensive processes and toxic chemicals. The protein fibril sponge method is far more sustainable, aligning with our commitment to environmentally responsible practices. This technology transforms two waste products—electronic waste and food industry byproducts—into valuable resources, reducing our environmental footprint.

Broader Application Potential: While electronic waste is the primary focus, the method can potentially be applied to other sources of gold, such as industrial waste from microchip manufacturing and gold-plating processes. This versatility could open up new revenue streams and processing opportunities for D Block Metals.

High Purity Gold Recovery: The method has demonstrated a high efficiency in recovering gold, producing 22-carat gold nuggets with a 91% gold content from electronic waste. This level of purity is crucial for meeting industry standards and customer expectations.

Looking Ahead

As ETH Zurich researchers continue to refine and develop this technology for market readiness, we remain interested in exploring its potential applications within our operations. The possibility of using other protein-rich byproducts to create the sponges further enhances the method’s sustainability and appeal. In conclusion, the discovery of this innovative gold recovery method is a big step forward for the refractory and precious metal processing industry. At D Block Metals, we’re excited about the prospects of integrating such novel technologies to enhance our efficiency and sustainability and we look forward to testing its capabilities once it is ready for the markets.

Click here to learn more about ETH Zurich’s research on turning waste into gold.