The Hard Metals Industry

Recycling metals has become increasingly important in the Hard Metals industry, transforming the way this sector sources and utilizes materials. Hard metals (also known as cemented carbides or sintered metals) are crucial for applications demanding exceptional hardness, wear resistance and high-performance cutting. However, the complex composition and scarcity of some metals, such as tungsten and cobalt has instigated the adoption of metal recycling practices. In this context, recycling metals for the Hard Metals industry not only offers economic advantages but also aligns with sustainability goals and the responsible management of finite resources.

The Hard Metals Industry

Recovering & Processing Metals

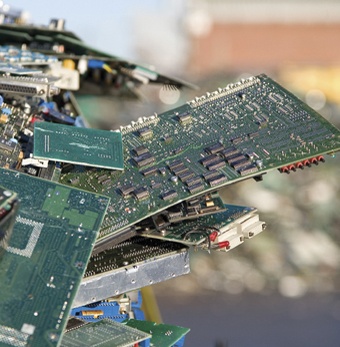

Resource Conservation and Sustainability: By specializing in the recovery and processing of metals like tantalum, tungsten, cobalt, and chromium from used cutting tools, industrial waste, and discarded hard metal products, we help ensure a sustainable and continuous supply of essential raw materials. This approach significantly reduces the demand for new primary extraction and helps conserve valuable resources.

Materials Expertise and Processing: The complex composition of Hard Metals requires specialized processing techniques to recover valuable metals effectively. We possess the technical expertise to efficiently extract and refine metals from hard metal scrap. Through advanced methods such as mechanical shredding, separation, and metallurgical processes, we transform discarded materials into high-quality materials for the hard metal industry.

Circular Economy Integration: Our collaboration with the Hard Metals industry exemplifies the principles of the circular economy. By reusing and recycling metals, we help contribute to a closed-loop system where materials are continuously circulated and repurposed.

Recovering & Processing Metals

Carbide Grade Tantalum Oxide

Carbide Grade Tantalum Oxide

Recycling metals to produce carbide-grade tantalum oxide is an important piece of the Hard Metals industry. This process involves the reclamation and transformation of discarded tantalum-containing materials into high-quality carbide-grade tantalum oxide. This oxide serves as a crucial precursor in the production of tantalum carbonate, a key ingredient in the hard metals manufacturing process. By utilizing recycled tantalum materials, this approach not only conserves valuable resources but also reduces the industry’s dependence on primary tantalum extraction, which can be both environmentally taxing and economically intensive. Processing recycled materials in order to produce carbide-grade tantalum oxide is just one of many ways we remain committed to serving the needs of the Hard Metals industry.

Our role in supplying the Hard Metals industry with recycled metals shows a strong commitment to both environmental stewardship and industrial progress. By transforming discarded metals into high-quality materials such as carbide-grade tantalum oxide, a critical precursor for tantalum carbonate production, we contribute to the sustainability and circularity of the industry. This collaboration not only ensures a steady supply of essential materials but also reduces the Hard Metals industry’s reliance on primary mining and helps minimize the impact on the environment.