The Superalloy Industry

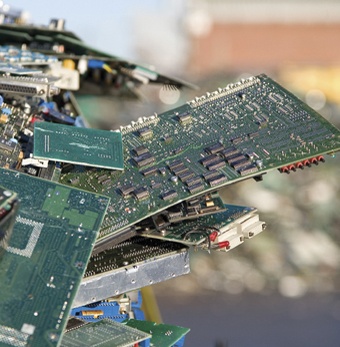

The Superalloy industry relies heavily on the recycling of metals to meet its demands for high-performance materials. Superalloys are specialized alloys designed to withstand extreme temperatures and harsh environments, making them essential for aerospace, energy, and other industries. However, the production of superalloys requires a significant amount of rare and valuable metals which can be costly and environmentally taxing to extract through traditional mining methods.

The Superalloy Industry

Supplying The Superalloy Industry

Reliable Supply of Crucial Metals: D Block Metals plays a pivotal role in serving the Superalloy industry by providing a reliable supply of crucial metals. We specialize in the collection, processing, and recycling of metal scrap, including Superalloy components. By efficiently recovering and refining metals like nickel, cobalt, tantalum, hafnium, and titanium metal we help ensure a sustainable and consistent supply of these key elements to the Superalloy industry, reducing the industry’s dependence on primary metal extraction.

Cost-Effective Solution: D Block Metals utilizes advanced techniques to extract valuable metals from scrap materials, eliminating the need for expensive and environmentally damaging mining operations. By leveraging economies of scale and efficient recycling processes, we provide Superalloy manufacturers with recycled metals at competitive prices.

Environmental Sustainability: The extraction and processing of metals through conventional mining methods are often associated with significant environmental impacts, including habitat destruction, water pollution, and carbon emissions. By recycling metals, we reduce the need for new metal production thus conserving natural resources and minimizing the carbon footprint of the Superalloy industry.

Supplying The Superalloy Industry

The Importance Of Recycling Tantalum & Hafnium For The Superalloy Industry

The Importance Of Recycling Tantalum & Hafnium For The Superalloy Industry

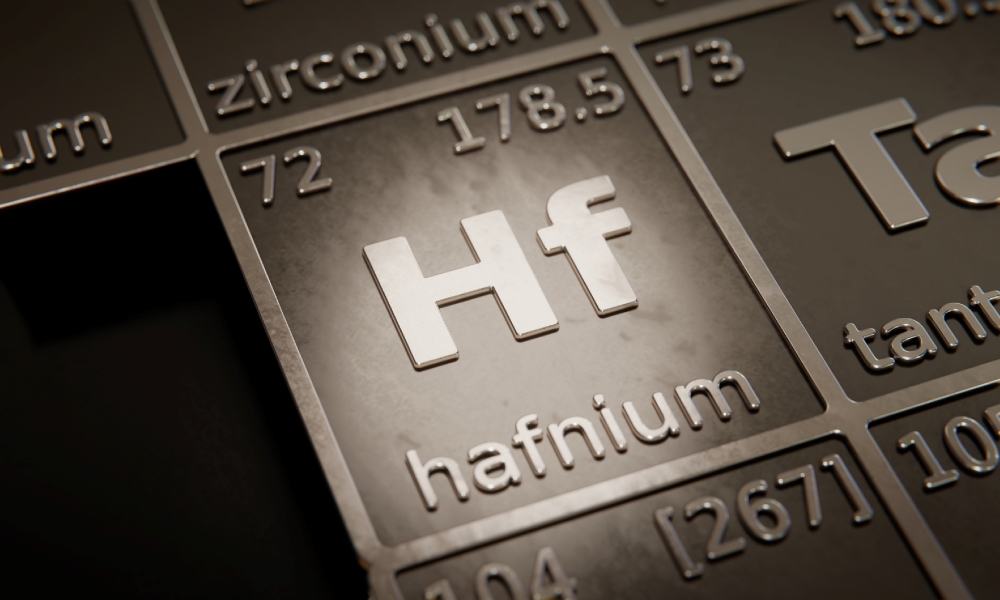

Recycled Hafnium and Tantalum play a crucial role in the Superalloy industry due to their unique properties and limited availability. Hafnium, a highly refractory metal, and Tantalum, known for its excellent corrosion resistance, are essential components in the production of Superalloys. However, the scarcity and high cost associated with primary extraction make the recycling of these metals of the utmost importance. By recycling Hafnium and Tantalum, the Superalloy industry can ensure a sustainable and consistent supply of these critical elements. Recycling these scarce metals not only reduces the reliance on primary mining but also contributes to environmental sustainability.

D Block Metals plays a pivotal role in serving the Superalloy industry by providing recycled metals such as Tantalum and Hafnium. By specializing in the collection, processing, and recycling of metal scrap, we help ensure a reliable and sustainable supply of these crucial elements. Through efficient extraction and refining processes, we offer cost-effective solutions that reduce the industry’s dependence on primary metal extraction. Our supply of recycled metals enables the Superalloy industry to continue developing high-performance materials, fostering innovation and progress in aerospace, energy, and other sectors that rely on materials capable of withstanding extreme conditions. Ultimately, our efforts contribute to the circular economy by promoting environmental sustainability and the long-term viability of the Superalloy industry.