ShAPE’s Impact On Scrap Metal Markets

Date

The Pacific Northwest National Laboratory’s (PNNL) patented ShAPE (Shear Assisted Processing and Extrusion) process has the potential to significantly impact the scrap metals market through its innovative approach to metal processing and recycling.

Traditional metal recycling methods often involve melting down scrap metals to form new materials, which can be energy-intensive and may result in a loss of material properties. In contrast, the ShAPE process offers a more sustainable and cost-effective solution by allowing for the direct recycling of scrap metals without the need for melting.

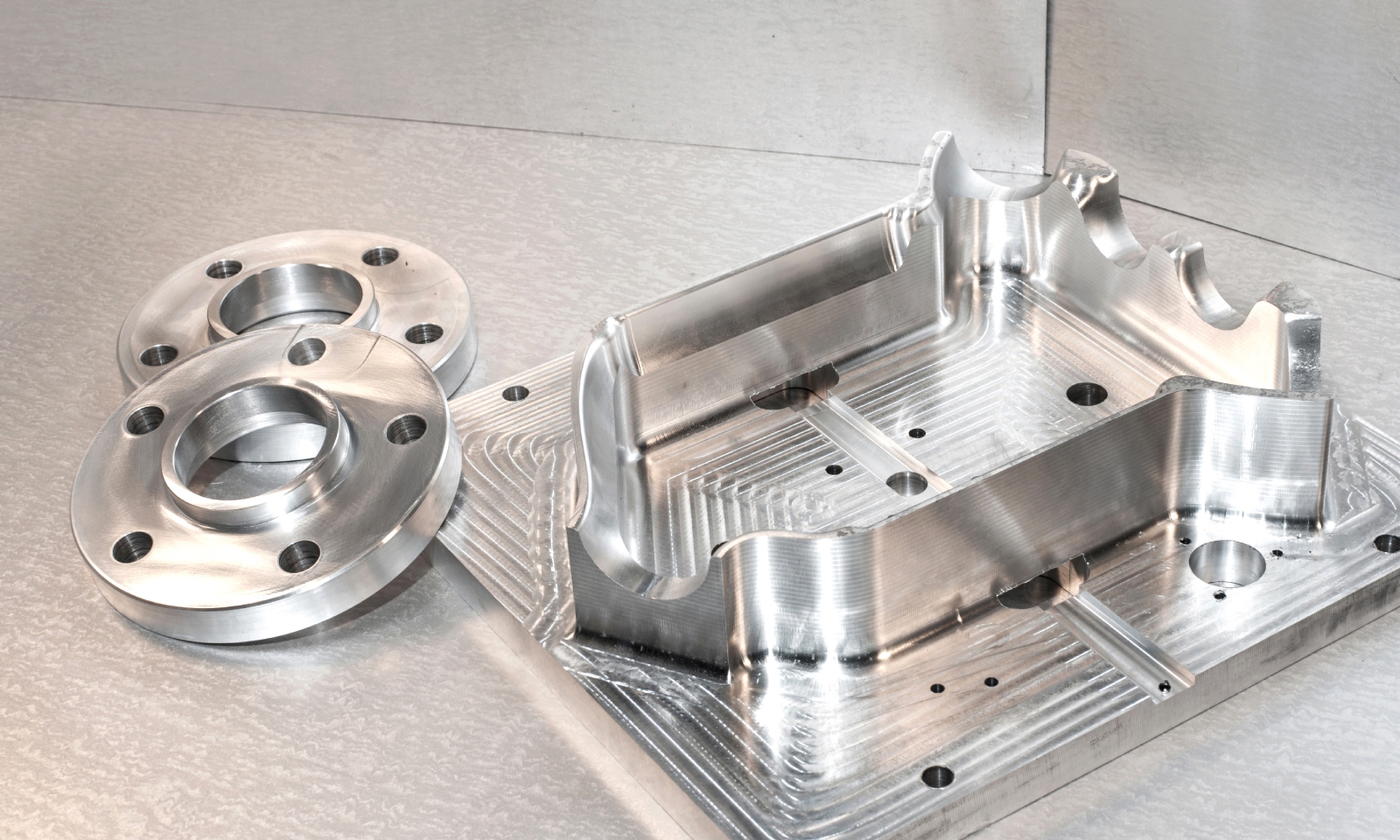

By utilizing high-pressure shear and extrusion techniques, the ShAPE process enables the rapid shaping and forming of metal alloys at relatively low temperatures. This not only reduces energy consumption but also preserves the mechanical properties of the original materials, resulting in higher-quality recycled products.

The implementation of the ShAPE process in the scrap metals industry could lead to several key benefits:

- Reduced Waste: The ability to directly process scrap metals into new products minimizes the amount of waste generated during the recycling process, thereby reducing environmental impact.

- Cost Savings: By eliminating the need for melting and refining processes, the ShAPE process can lower production costs for manufacturers, making recycled materials more economically viable.

- Improved Material Properties: Unlike traditional recycling methods that can degrade material properties, ShAPE maintains or even enhances the mechanical properties of recycled metals, expanding their potential applications.

- Market Competitiveness: With a more efficient and sustainable recycling solution, companies utilizing the ShAPE process may gain a competitive edge in the market, attracting environmentally-conscious consumers and businesses.

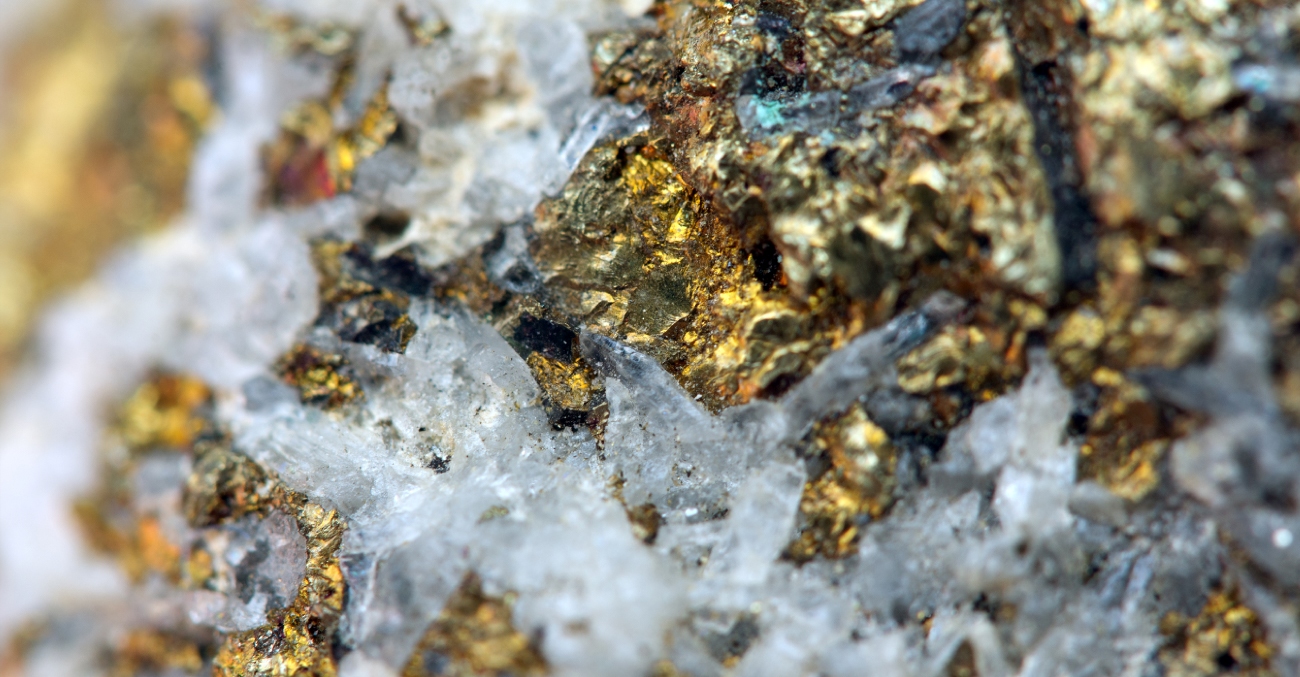

- Supply Chain Resilience: By offering a more efficient means of recycling scrap metals, the ShAPE process contributes to the resilience of the metal supply chain, reducing reliance on finite natural resources and decreasing the frequency of supply chain disruptions.

Overall, the widespread adoption of the ShAPE process in the scrap metals industry has the potential to stir-up metal recycling by offering a more sustainable, cost-effective, and environmentally-friendly alternative to traditional methods. As a result, it could reshape the dynamics of the scrap metals market, driving increased demand for recycled materials and promoting a more circular economy.