A Metal Recycling Breakthrough in Electrochemistry

Date

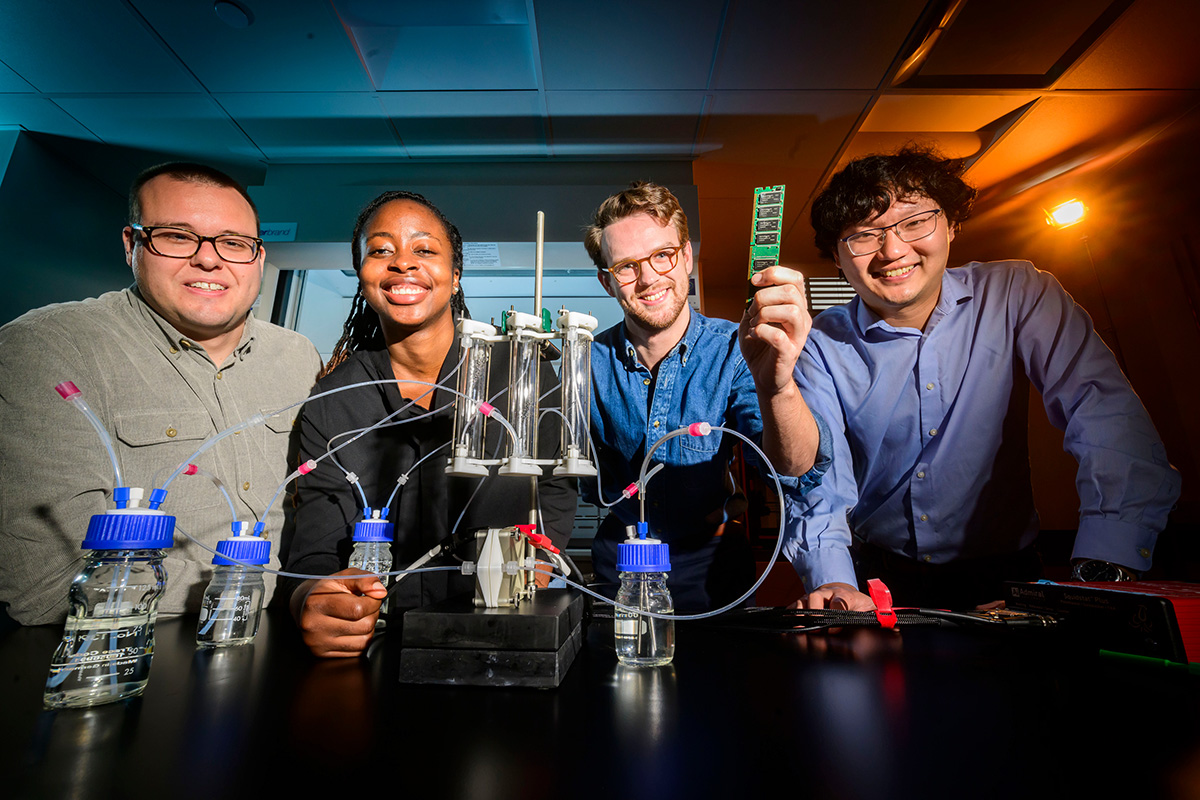

A new study shows how electrochemistry can be used to extract precious metals from discarded electronics in an efficient and environmentally friendly manner. - Photo by Fred Zwicky

University of Illinois Urbana-ChampaignSource: www.illinois.edu

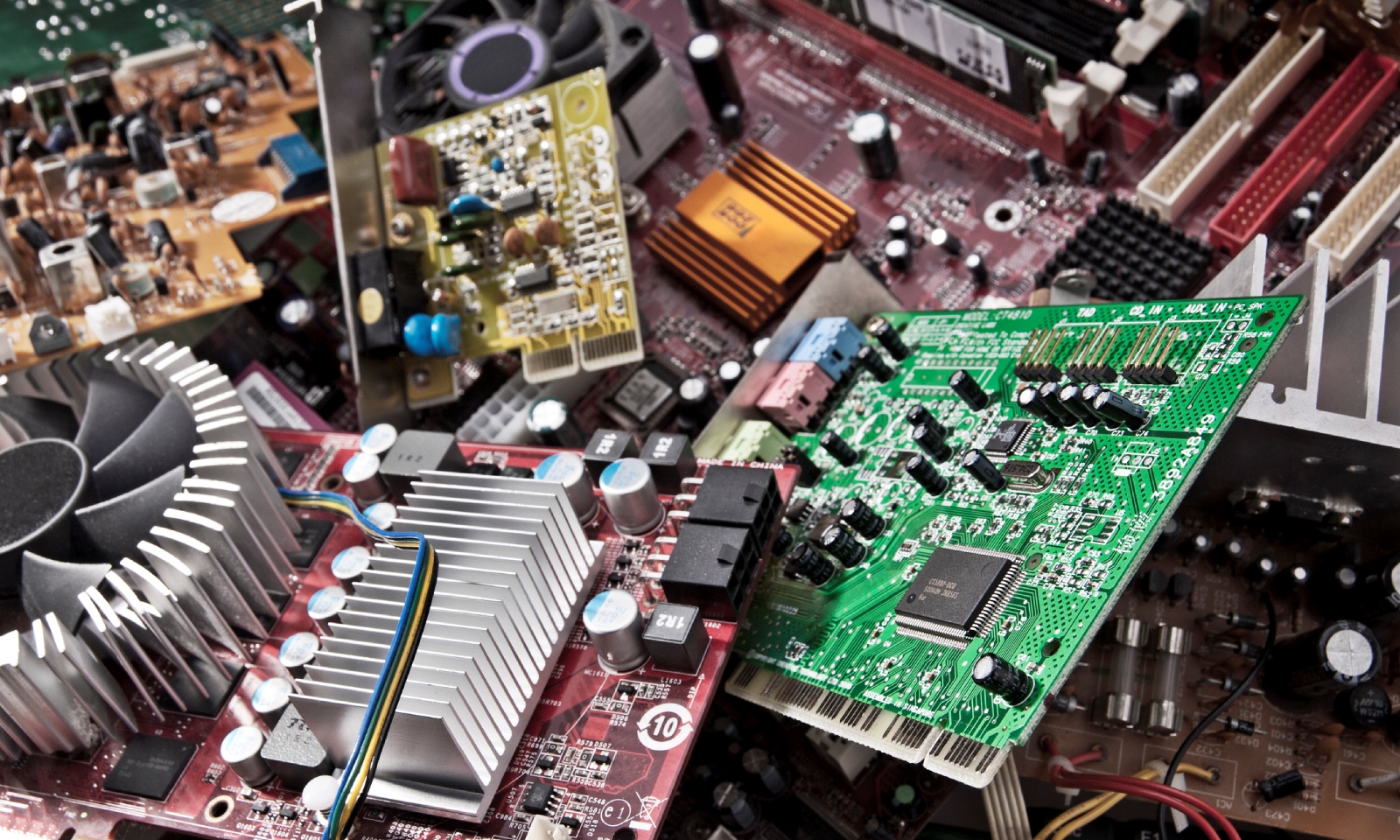

The pursuit to extract precious metals from discarded electronics and low-grade ores has long been a challenge marked by high energy consumption and environmental impact. However, a recent groundbreaking discovery by researchers at the University of Illinois Urbana-Champaign promises a paradigm shift. Their innovative electrochemical process, detailed in a study published in the prestigious journal Nature Chemical Engineering, offers a safer, more efficient, and environmentally friendly method of extracting valuable metals like gold, platinum, palladium, and iridium.

Photo by Fred Zwicky

Led by Professor Xiao Su from the Department of Chemical and Biomolecular Engineering, the research team introduced a novel approach powered by electrochemical liquid-liquid extraction (e-LLE). Unlike traditional methods that rely heavily on energy-intensive processes and extensive chemical materials, this new technique harnesses the inherent energy of reduction-oxidation reactions to selectively extract precious metal ions from liquid solutions containing dissolved electronic waste or low-grade ores.

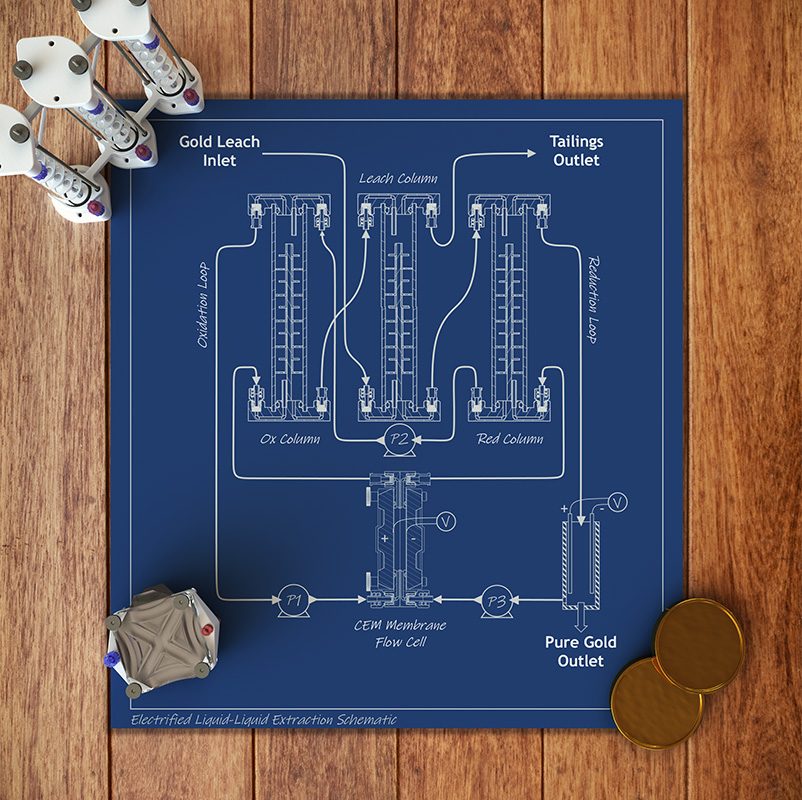

The process involves dissolving electronic waste components such as catalytic converters and old circuit boards, along with simulated mining ores containing target metals, in an organic solvent. The dissolved mixture then passes through specialized electrodes arranged in three sequential extraction columns: one for oxidation, one for leaching, and one for reduction. This systematic approach efficiently separates the desired metals from the solution, which are then solidified through electroplating. The remaining liquid, including the organic solvent, undergoes further treatment to capture any residual metals for recycling purposes.

-Graphic courtesy Xiao Su

What sets this method apart is not only its energy efficiency but also its ability to operate continuously in an environmentally sustainable manner. Professor Su emphasized the technique’s high selectivity, enabling the extraction and separation of precious metals like gold and platinum group metals from other less valuable metals present in the solution, such as silver, nickel, and copper. This level of precision significantly enhances the purity of the extracted metals, a feat that conventional methods often struggle to achieve.

In addition to its technical advantages, the economic viability of this approach is just as compelling. An economic analysis revealed that the new method operates at a significantly lower cost compared to existing industrial processes, marking a potential shift towards more cost-effective and sustainable practices in the precious metal extraction industry. Postdoctoral researcher Stephen Cotty, the first author of the study, highlighted the social value of this innovation, emphasizing its role in producing “green gold” with enhanced transparency and trust in conflict-free recycled precious metals.

Looking ahead, the research team is dedicated to refining and optimizing the electrochemical extraction process. This includes improving engineering designs and selecting optimal solvents to further enhance efficiency and reduce environmental impact. The implications of this breakthrough extend beyond academic realms, with potential applications in industries reliant on precious metals, such as electronics manufacturing and renewable energy technologies.

The support from the U.S. Department of Energy places a strategic importance on this research in advancing sustainable resource management and reducing the carbon footprint associated with traditional extraction methods. Furthermore, the University of Illinois Urbana-Champaign’s filing of a provisional patent reflects the potential for real-world implementation and commercialization of this transformative technology.

The newly discovered electrochemistry process for extracting precious metals represents a significant leap forward in sustainable resource utilization. By minimizing energy consumption, reducing chemical waste, and improving metal purity, this innovation paves the way for a more environmentally conscious and economically viable approach to meeting the global demand for precious metals while minimizing the environmental impacts of traditional extraction practices.