Beer’s Surprising Role in Recycling Electronic Waste

Date

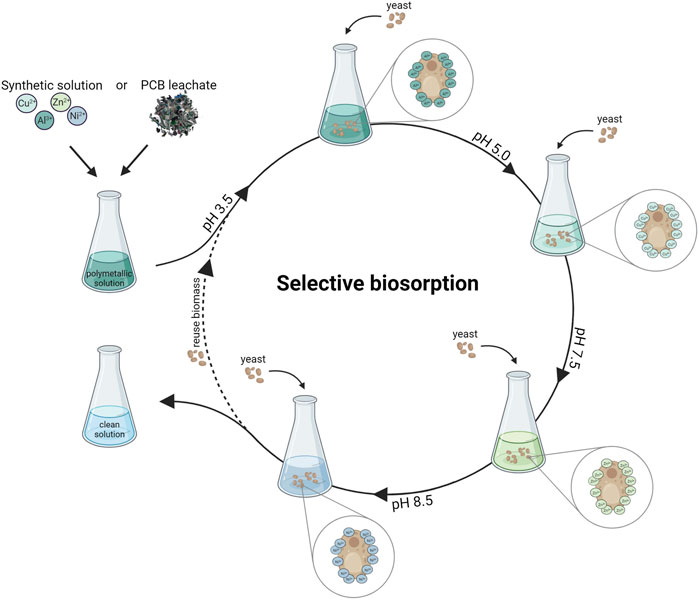

In this study, an environmentally friendly and selective biosorption approach, based on the pH-dependency of metal sorption processes is presented using spent brewer’s yeast to efficiently recover metals like aluminum, copper, zinc and nickel out of polymetallic solutions.

FrontiersSource: www.frontiersin.org

In the ongoing pursuit of sustainable practices, a groundbreaking discovery by Austrian scientists has high hopes to revolutionize electronic waste recycling. Leveraging an unexpected resource from beer production—spent brewer’s yeast—researchers have developed an innovative and environmentally friendly method for extracting valuable metals from discarded electronics.

The Challenge of Electronic Waste Recycling

As our reliance on electronic devices continues to grow, so does the challenge of recycling them effectively. Electronic waste (e-waste) is a complex mix of metals like copper, zinc, and aluminum, making traditional recycling methods cumbersome and inefficient. These metals are often entangled within electronic components, posing a significant hurdle to separation and recovery processes.

The Role of Brewer’s Yeast in Metal Recovery

Enter brewer’s yeast, a byproduct of beer manufacturing that typically garners less attention than its primary purpose. However, recent research published in Frontiers in Bioengineering and Biotechnology sheds light on its newfound potential. Dr. Klemens Kremser of the University of Natural Resources and Life Sciences in Vienna highlights the innovative nature of this research, emphasizing the challenge posed by e-waste’s heterogeneity.

The breakthrough lies in utilizing brewer’s yeast for its selective metal recovery properties through a process called adsorption. This process relies on electrostatic interactions, where metals in a solution adhere to the yeast. By adjusting the pH levels, researchers can optimize this adsorption process, enhancing the yeast’s ability to absorb specific metal ions efficiently.

Significant Findings and Environmental Impact

In their experiments, the research team achieved impressive metal recovery rates: over 50% of aluminum, 40% of copper, and a remarkable 70% of zinc from simulated metal waste streams. The method also exhibited selectivity, with more than 50% of copper and over 90% of zinc successfully recovered from real polymetallic waste streams.

Moreover, the process showcases environmental benefits, being both cost-effective and eco-friendly. Anna Sieber, a doctoral student involved in the research, highlights the importance of this discovery in achieving high metal recovery rates from complex metal solutions using an environmentally friendly biomass.

Looking Towards the Future

While the potential of this method is promising, the researchers caution that further studies under real-world conditions are necessary before industrial-scale deployment. Optimizing the process for broader applications and considering potential interference from other metal ions are key challenges that require thorough investigation.

Nevertheless, the implications are profound. This innovative approach not only addresses the pressing issue of e-waste but also contributes to reducing heavy metal pollution. By turning waste into a valuable resource, we move closer to a circular economy model, where every waste product becomes an opportunity for resource recovery.

Beer’s humble byproduct, brewer’s yeast, has emerged as an unexpected helper in the search for sustainable practices, offering a glimpse into a future where recycling electronic waste is both efficient and environmentally conscious.